We all know that you should have a filter on your air conditioning or heating systems. These filters primary purpose is to protect the equipment from large amounts of dust, dirty, and anything that could get sucked into the furnace, air handler, or ductwork and cause damage or an obstruction.

Most HVAC/R technicians can tell you stories about finding plastic bags, dog toys, fur, marbles, Lego’s, and just about anything else you can imagine in the ductwork, blower wheels, and blocking the air conditioning evaporator (inside) coils. Anything affecting the free movement of air (air flow) is costing you money and negatively affecting the performance of your system. In the case of heating, it is possible that flammable material sucked into the system can cause a fire. In the case of air conditioning material that blocks air flow can eventually cause compressor failure. So, filters are important.

Having said that there are occasions that filters can also be the source of the problem. In years past return air filters used to be made out of a loose weave fiberglass. In fact you can still find these in the stores today. If you hold them up to the light you can see through them.

As time went on the industry realized that filters can actually help improve air quality in the building be filtering smaller size particles of dist. So, along came the paper pleated filters. The paper has smaller microscopic holes for the air to flow through and captures more dust. But, also it restricts airflow as well.

And, in more recent years the filter manufactures started making tighter and tighter weaves, as well as adding adhesive materials to make the filters even tighter still. Now some filters are tested to filter 90+ percent of all particles sent through them. Very small holes for air to move through.

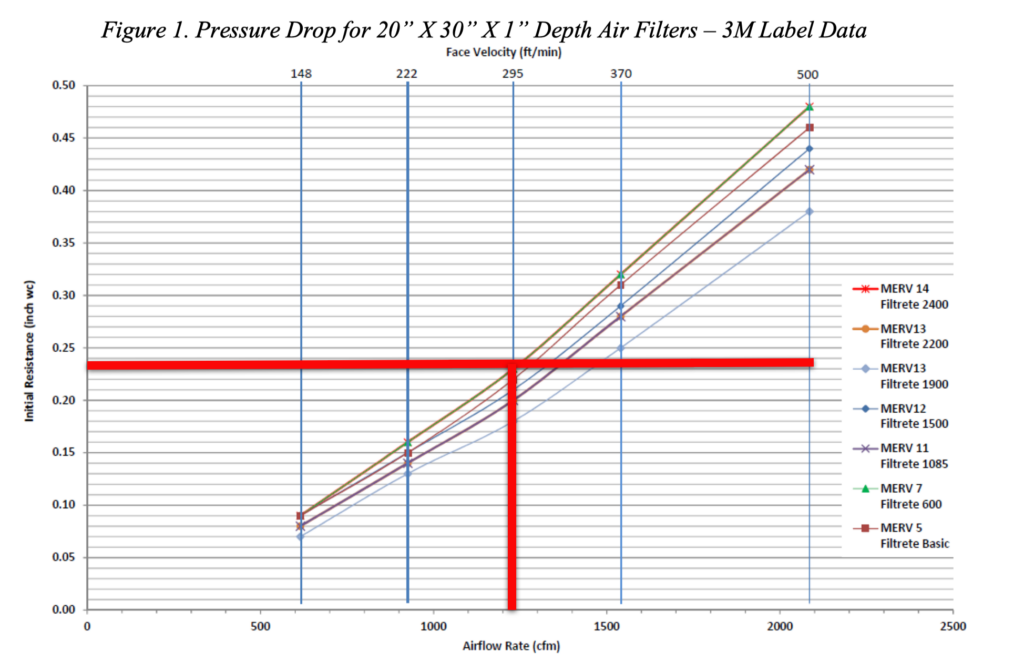

There is a simple rule to remember: The more efficient a filter is in capturing particular matter, the less efficient it is for allowing air flow. Every filter has a manufactures rating that says, “for this size of filter, and this MERV (the official rating of particle capture) rating, this is the amount of air that can pass through it.

Air conditioning requires 400CFM (cubic feet per minute per ton of cooling).

In the above diagram we have a rated restriction (static pressure drop) of .20″ WC (a standard measurement of air flow and air pressures in an HVAC system). The curved lines are the static pressure drop of the filter at various CFM’s (volume of air). Remember, we must have 400CFM per ton of cooling. So, for these filters (MERV Ratings and colors on right side) and in most residential and light commercial systems we cannot handle air volumes over 1250 CFM of air for this size of filter, regardless of the MERV rating. So, a 20 x 30 x 1 filter (which is a pretty good sized filter) cannot handle air flows required for anything over a 3 ton system (400CFM x 3 Ton = 1200 CFM). And, that is when the filter is new. As it becomes filled with dust and dirt the resistance (pressure drop) will not get better, it gets worse.

But, before you go nuts looking for filter labels, take a look at your filter with the system running in cooling mode (heating takes slightly less airflow if you have a gas or oil system, if you have electric heat or a heat pump you can use heating as well). If the filter is sucking into the return grill, bowed inwards, or pulling into the system out of the frame, you have a restriction that is negatively impacting your equipment.

First make sure the filter is clean. If it is clean, you are using a filter that is too tight (restrictive) for your system. Back off and go to a slightly looser filter. if you are using a high efficiency (high MERV rating) filter, back off the the looser generic paper pleated filter. If you are using a paper pleated filter, back off and go to the fiberglass.

The correct filter will go a long way to making sure your equipment as a very long life span. The correct filters are cheap compared with equipment costs.